Why CAD Design Is Crucial in Sheet Metal Fabrication

In today’s manufacturing landscape, CAD design for sheet metal fabrication is no longer optional — it’s essential. Computer-Aided Design (CAD) allows manufacturers to create highly accurate technical drawings, simulate assemblies, and optimize every step of the production process.

From simple flanges and brackets to full machine frames or control cabinets, CAD ensures precise dimensions, clear specifications, and error-free production — right from the first prototype.

HD Mechanical Vietnam- CAD Design Company in Vietnam

HD Mechanical Vietnam is a trusted name in sheet metal fabrication and CAD design, with over 10 years of experience serving domestic and international clients.

We support projects in various sectors: automation, robotics, electrical enclosures, conveyor systems, mechanical parts, and more.

Our Quality Commitment

-

CAD drawings with high precision and manufacturing compatibility

-

Compliance with industry standards: ISO, JIS, DIN

-

File confidentiality guaranteed – NDA available upon request

CAD Design Capabilities of HD Mechanical Vietnam

Experienced CAD Engineers

-

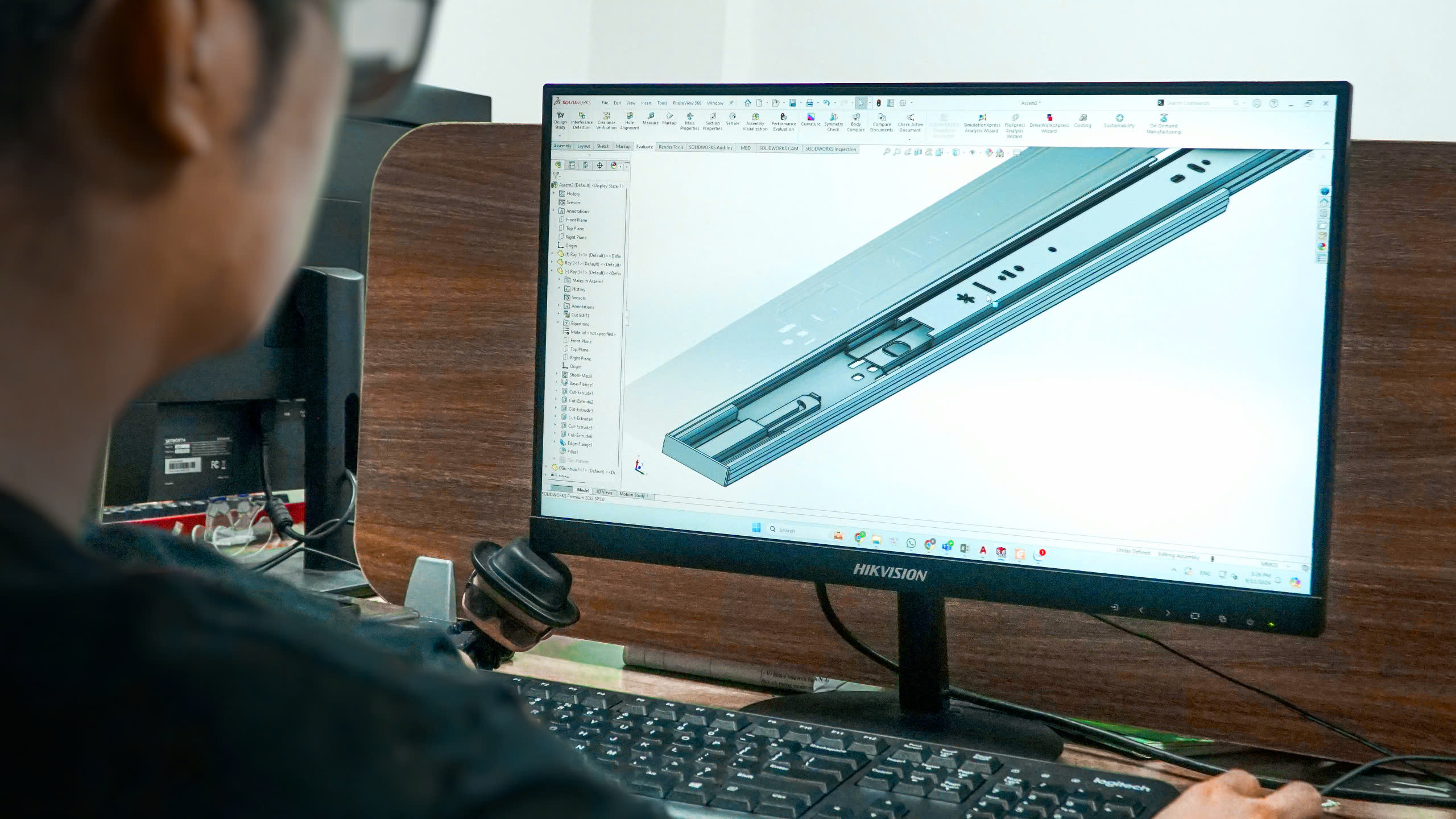

Skilled in AutoCAD, SolidWorks, Inventor, DraftSight

-

Hands-on expertise from 2D drafting to complex 3D mechanical assemblies

End-to-End Design Workflow

-

Initial consultation and technical review

-

Detailed 2D/3D CAD drawings tailored for manufacturing

-

Full quality checks before final delivery

Design with Production in Mind

-

Optimized layouts using nesting, K-factor, and flat patterns

-

Design compatibility with: laser cutting, CNC punching, bending, welding, and more

Featured Projects of HD Mechanical Vietnam

Project 1: Industrial Control Cabinet – USA Customer

-

Designed a full enclosure and support frame

-

Addressed IP rating, cut-out layout, and cable routing precision

Project 2: Outdoor Mailbox – Japanese Partner

-

Optimized initial sketches into full standard production drawings

-

Delivered bilingual (Vietnamese – Japanese) assembly files

Project 3: Steel Post and Fence – UK Client

-

48-hour turnaround for urgent design request

-

Remote collaboration via Whatsapp, Zoom, and email ensured timely delivery

Why Choose HD Mechanical for CAD Design?

-

Faster production lead time

-

Reduced prototyping & error costs

-

Designs customized to your existing machinery

-

Full file confidentiality – NDA-ready

-

Flexible formats: DWG, DXF, STEP, PDF…

Whether you’re developing a new product or optimizing an existing one, we ensure your designs are ready for seamless manufacturing.The CAD design services we provide are at the conceptual part of the rest of the business. We utilize CAD service for producing:

Get a Free CAD Consultation Today

Need fast, professional CAD design for your next sheet metal project?

-

Free consultation with expert engineers

-

File adjustments and optimization for cutting & bending

-

Support from concept to production-ready CAD drawings

Contact us now via Email: kim@haiduongmp.com

More Product

Connect with us on other platforms