Why Choose Professional Laser Cutting Services?

In the world of metal fabrication, laser cutting services are essential for achieving precision, efficiency, and cost-effectiveness. At HD Mechanical Vietnam, we offer high-quality laser cutting solutions designed to meet the needs of industrial manufacturers, construction firms, and custom metal fabricators.

- Fast & Precise Cutting – Advanced laser technology ensures clean, accurate cuts

- Cost-Effective Production – Reducing material waste and increasing efficiency

- Versatile Applications – Suitable for stainless steel, aluminum, galvanized steel, and more

- Custom Designs & Bulk Orders – High-volume production with consistent quality

1. What is Laser Cutting?

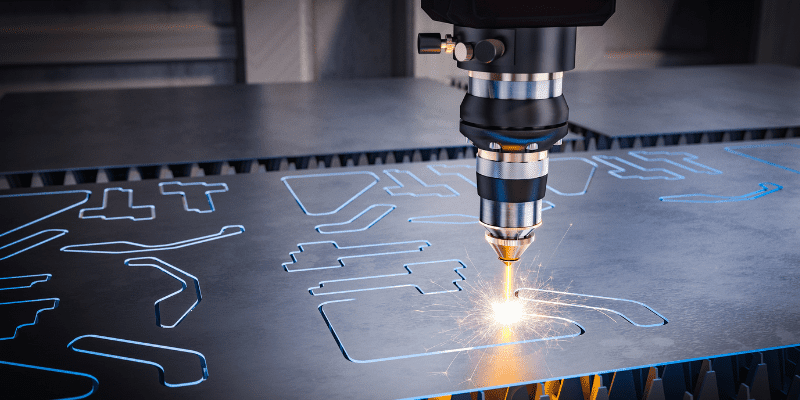

Laser cutting is a non-contact manufacturing process that uses a high-powered laser beam to cut, engrave, or etch various types of metal and materials. This process is widely used in industries like automotive, aerospace, electronics, and metal fabrication due to its accuracy and efficiency.

2. Our Expert Laser Cutting Capabilities

At HD Mechanical Vietnam, we specialize in high-precision laser cutting with the latest CNC laser technology, offering:

- Material Compatibility: Stainless steel, aluminum, mild steel, galvanized steel, and more.

- Cutting Thickness: From 0.5mm to 25mm, ensuring flexibility for different applications.

- High Accuracy: ±0.1mm precision, reducing errors and rework.

- Custom Metal Parts: Intricate patterns, industrial components, signage, and decorative pieces.

3. Benefits of Our Laser Cutting Services

– Superior Precision & Quality

- Smooth edges with minimal burrs

- No mechanical stress on the material

- Perfect for complex shapes & detailed designs

– Faster Production Time

- High-speed cutting for large-scale manufacturing

- Ideal for mass production & custom orders

– Cost-Effective & Eco-Friendly

- Reduces material waste

- Optimized energy efficiency

– Versatility Across Industries

- Used in industrial manufacturing, construction, electronics, and automotive industries

4. Industries We Serve

Our laser cutting services cater to various industries, including:

- Metal Fabrication – Custom metal parts for industrial applications

- Automotive – Precision-cut components for vehicles

- Construction & Architecture – Structural metal parts, signage, and panels

- Packaging & Retail Displays – Custom metal packaging solutions

- Electronics & Machinery – Small, intricate metal parts for devices

5. Our Advanced Laser Cutting Process

We follow a strict quality-controlled process to ensure perfect results:

- Step 1: Consultation & Design – Discussing project requirements, material selection, and technical drawings.

- Step 2: CAD File Preparation – Creating high-precision digital blueprints for laser cutting.

- Step 3: Laser Cutting Execution – Using CNC-controlled laser technology for flawless cutting.

- Step 4: Quality Inspection – Checking dimensions, edges, and accuracy before shipment.

- Step 5: Final Finishing & Delivery – Surface treatment, powder coating, or additional processing if required.

Why Choose HD Mechanical Vietnam for Laser Cutting?

- State-of-the-Art Technology – Using the latest fiber and CO2 laser cutting machines

- Skilled Experts – Experienced team ensuring high-quality results

- Competitive Pricing – Cost-effective solutions for bulk & custom orders

- Fast Turnaround Time – Meeting deadlines with efficient production

- Global Shipping – Reliable worldwide delivery with secure packaging

Get a Quote for Your Laser Cutting Project Today!

Looking for expert laser cutting services with high precision and efficiency? HD Mechanical Vietnam is your trusted partner! Laser cutting is a cutting-edge technology that offers unparalleled precision, efficiency, and versatility for manufacturing processes. Our manufacturing workshop specializes in providing laser cutting services, utilizing state-of-the-art machinery and a team of skilled professionals. Whether you require custom designs, prototypes, or high-volume production, our laser-cutting services will meet your needs with exceptional accuracy, speed, and quality. Contact us today to discuss how our laser-cutting capabilities can benefit your manufacturing operations.

Our CNC laser cutting service is only one part of our sheet metal engineering capabilities. At our mechanical and engineering company in Vietnam, we provide a sheet metal and general manufacturing services for wide range of products, including:

- Customized Wall-mounted Mailbox

- Large Parcel Letterboxes

- Oval Raised Garden Bed

- Aluminum Table Legs

- Electrical Enclosure

For the consistent production of accurate parts that meet tight tolerances, you can contact the team here at HD Mechanical Vietnam for your entire CNC laser cutting services.

More Product

Send us an E-mail for long-term cooperation

Connect with us on other platforms